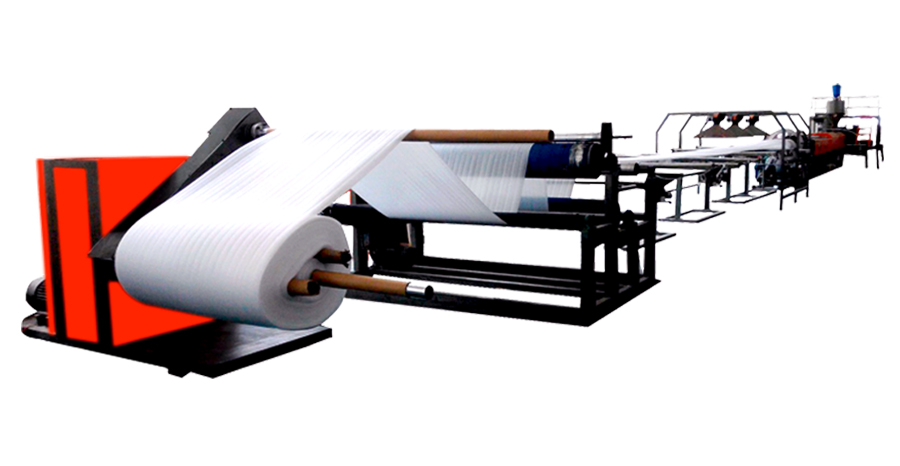

EPE Foam Extrusion Machine

EPE foam sheet extrusion machine

Process flow:

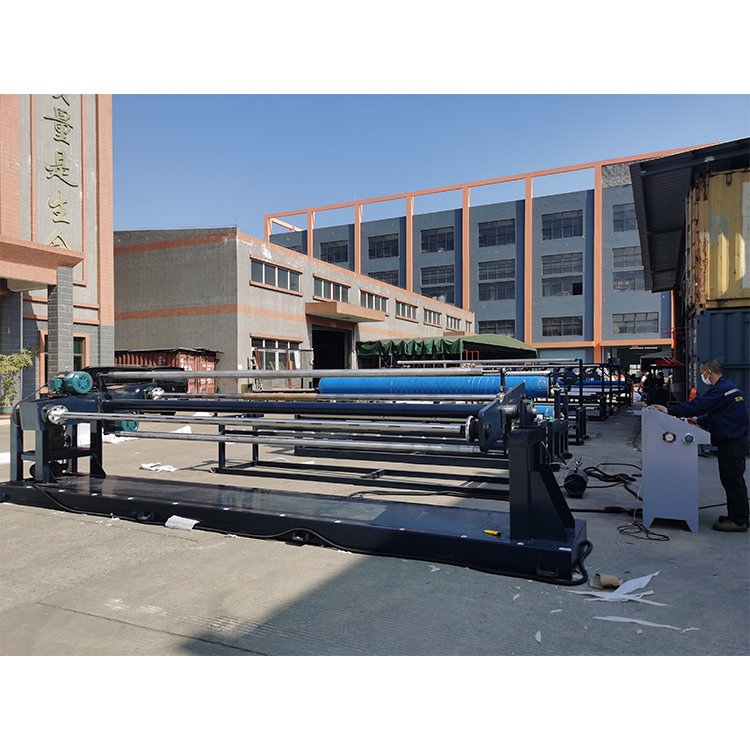

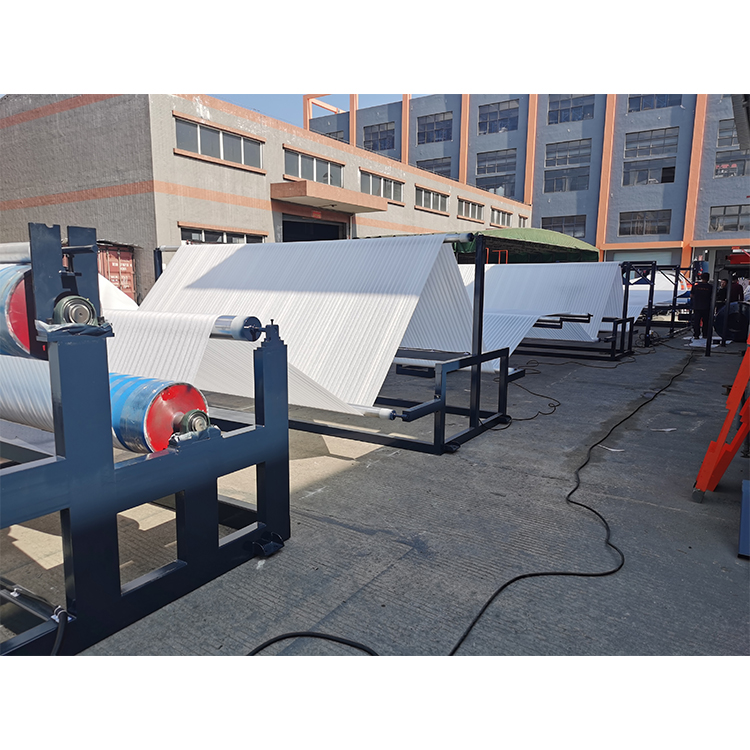

Plastic granules → formula mixing → heating → blowing agent injection → mixing plasticization → extrusion → cooling forming → sizing and cutting → cooling traction → flattening → winding → EPE Foam sheet

First, mix polyethylene and other raw materials uniformly, put them into the hopper of the extruder, melt and knead through the extruder with a large aspect ratio, and at the same time inject the foaming gas - butane gas and the molten monoglyceride into the middle of the extruder at high pressure. It is uniformly mixed with the melted and kneaded plastic, extruded by the machine head and die, and then cooled, drawn, flattened, and wound to form a foamed sheet product.

Technical Parameter:

| Model 型号 | Screw Dia 螺杆直径 | Screw L:D 螺杆长径比 | Output 生产能力 | Thickness 产品厚度 | Width 产品宽度 | Foaming times 发泡倍率 | Total power 总功率 | Dimension 安装尺寸 | Weight 机器 重量 |

| FLY-170 | 170mm | 55:1 | ≤400kg/h | 2-15mm | ≤1800mm | 16-47 | 250kw | 32000 x 2800 x 2800mm | 15t |

| FLY-180 | 180mm | 55:1 | ≤450kg/h | 2.5-18mm | ≤2000mm | 15-60 | 300kw | 37000 x 2800 x 3500mm | 16t |

| FLY-200 | 200mm | 55:1 | ≤550kg/h | 2.5-20mm | ≤2000mm | 15-60 | 350kw | 38000 x 2800 x 3800mm | 17.5t |

| FLY-220 | 220mm | 55:1 | ≤700kg/h | 2.5-25mm | ≤2000mm | 15-60 | 420kw | 42000 x 2800 x 3800mm | 20t |

| FLY-250 | 250mm | 55:1 | ≤800kg/h | 2.5-25mm | ≤2000mm | 15-60 | 480kw | 45000 x 2800 x 3800mm | 25t |